Project Galleries – Manufacturing

Robotic Manufacturing Cell

Client: Bradken

Value: $4M

Project Details: Manufacturing facility including robot, automatic saw with magazine, CNC lathe, heat treatment oven, induction hardening unit and packing stations.

Services Provided: GRG provided project management services throughout the implementation phase.

MAPS Emission Control

Client: Boral Cement

Value: Confidential

Project Details: Companies operating coal fired boilers for electricity generation are challenged to remove multiple pollutants from their flue gases in order to meet environmental regulations. The MAPS (Multiple Air Pollutant Control System) process concurrently removes SO2, SO3 and NOx, along with mercury (Hg) and fine (PM 2.5) particulate matter, in a unique single, fully retrofit, add-on device. The Indigo MAPS process incorporates chemical, physical and electrostatic processes to accomplish emissions removal. All sorbents and reagents used in the Indigo MAPSystem are sustainable chemicals with by-products that can be recycled.

Services Provided: GRG was engaged for design and drafting services for this leading edge air pollutants system.

Odour Extraction Fan

Client: Confidential

Value: Confidential

Project Details: GRG’s client requested assistance in determining the best location for a new odour extraction fan and stack and also the slab on which it would sit. The main design parameter was the consideration of minimal disturbance to the existing structure of the annealing annex and the main building.

Services Provided: Site visit, measuring and inspection of existing building structures including annealing building. 3D Drawings (AutoCAD Inventor 2017) incorporating the fan, additional roof trusses, conceptual supports, ducting (1200Ø and 1600Ø), and roof sheet penetrations.

Medical Device Manufacturing System

Client: Confidential

Value: Confidential

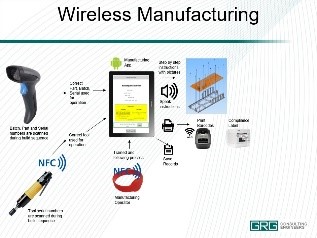

Project Details: Our client needed to develop and implement a manufacturing and assembly process for a ground-breaking innovative new commercial medical device. The assembly process needed to be controlled and consistent and required rigorous tracking and validation protocols compliant with US Code of Federal Regulations for the device to be sellable to US markets.

Services Provided: GRG custom-developed an android tablet-based manufacturing system to provide step by step real-time manufacturing instructions to assembly process technicians in a clean-assembly environment. GRG developed bespoke code for the android based software in-house and prepared assembly process planning and modelling. GRG’s implemented system was able to track operator inputs such as process step confirmation, tool, and part confirmation and a full set of validation protocols was developed such that the system was able to be successfully validated to the requirements of US Federal Regulations, specifically 21 CFR Part 11.

Brickworks Power Factor Correction Unit Advice

Client: Confidential

Value: Confidential

Project Details: Power Factor system had been experiencing instability since installation of solar system.

Services Provided: Inspected existing installation and compiled report on current condition and current instability. The report included analysis and findings regarding the installation, settings and identified deficiencies; and provided advice and recommendations for changes.

Other Recent Manufacturing Projects

- Bradken - Structural Engineering Reports

- Orrcon - Reliability Investigations

- Australian Country Choice - Site Layouts

- The Smiths Snackfood Company - Air-Conditioning Systems

- Bradken - Dust Collector and Enclosure Proposal

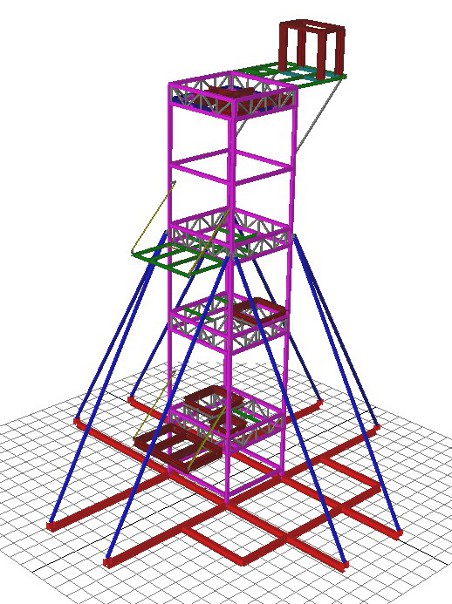

- Platforms, Structures and Lifting Devices